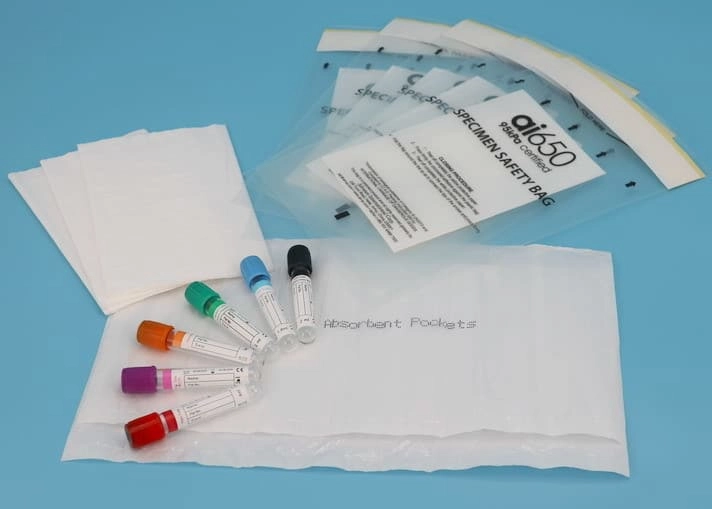

95 kPa specimen transport bag that complies with UN3373 packaging requirements

Release time: 2025-02-21

UN 3373 is the United Nations specification for the transport of biohazardous materials (including human and animal disease specimens). The specification specifically defines the packaging requirements for biological specimens for transportation, including pressure resistance, sealing, leakage prevention measures, and labeling.

95 kPa and UN 3373 specimen packaging requirements:

In the UN 3373 packaging requirements, the requirements for 95 kPa pressure test bags are mainly aimed at air pressure changes during air transportation. Specifically, air transportation often encounters air pressure changes, which may cause the gas in the container to expand or the change of external pressure, which may cause the liquid in the package to leak or the sample to be contaminated. Therefore, the packaging must be able to withstand 95 kPa pressure changes and ensure that it can experience a pressure difference of at least 95 kPa during transportation without rupture or leakage.

This requirement is not only to ensure the integrity of the packaging, but also to prevent environmental contamination, infection risks and loss of items caused by packaging damage.

UN 3373 requirements:

Inner and outer packaging system: A double-layer packaging system must be used. The inner packaging needs to be leakproof to ensure that liquids or cell materials, etc. will not leak. The outer packaging needs to be strong enough to prevent external damage.

Leak-proof design: Additional isolation measures must be required between the inner and outer packaging, usually using absorbent materials or airtight seals to ensure that internal leakage is effectively blocked when the outside is damaged. Especially for liquid specimens, the inner bag is required to be sealed and leak-proof to prevent sample leakage.

Pressure requirements: UN 3373 stipulates that specimen transport packaging bags must pass a 95 kPa pressure test during air transportation to ensure that there will be no leakage or container rupture at high altitudes or changes in air pressure. Packaging that meets this requirement must be designed and tested to maintain sealing under standard test pressure.

Labeling: Qualified UN 3373 packaging bags must clearly indicate the category of dangerous goods and be marked with appropriate biohazard symbols. This ensures that transporters and recipients can handle these items correctly to avoid accidents and misoperation.

The transport bags produced by AIC can withstand 95 kPa pressure changes and meet other requirements of the UN 3373 standard (such as double-layer packaging, leak-proof design, appropriate labeling, etc.). This ensures that during transportation, whether it is air pressure changes or physical shocks, it can effectively prevent leakage and contamination and ensure transportation safety.