What Is a kPa Bag?

Release time: 2025-03-04

Understanding Pressure Measurement in Specialized Packaging

When shopping for industrial, medical, or outdoor gear, you might stumble across terms like “kPa-rated bags” or “pressure-resistant packaging.” But what exactly does “kPa” mean, and why does it matter for a bag? Let’s unravel the science behind kPa bags, their applications, and why pressure resistance is critical in certain industries.

Breaking Down “kPa”

kPa stands for kilopascal, a unit of pressure widely used in scientific and engineering contexts. One kilopascal equals 1,000 pascals (Pa), and 1 Pa is defined as the force of one newton per square meter.

To put this into perspective:

Standard atmospheric pressure at sea level is approximately 101.3 kPa.

A car tire might be inflated to around 200–300 kPa.

Medical devices like ventilators often operate in the range of 5–20 kPa.

In the context of bags, kPa ratings indicate the internal or external pressure a bag can withstand without failing ,e.g., bursting, leaking, or deforming.

What Is a kPa Bag?

A kPa bag is a specialized container designed to endure specific pressure levels, measured in kilopascals. These bags are engineered with materials and seals that maintain integrity under stress, making them essential for:

Containing pressurized contents ,e.g., medical fluids, compressed gases.

Resisting external pressure ,e.g., underwater use, vacuum sealing.

Surviving transport or storage in extreme conditions ,e.g., high-altitude cargo, industrial machinery.

Common Applications of kPa Bags

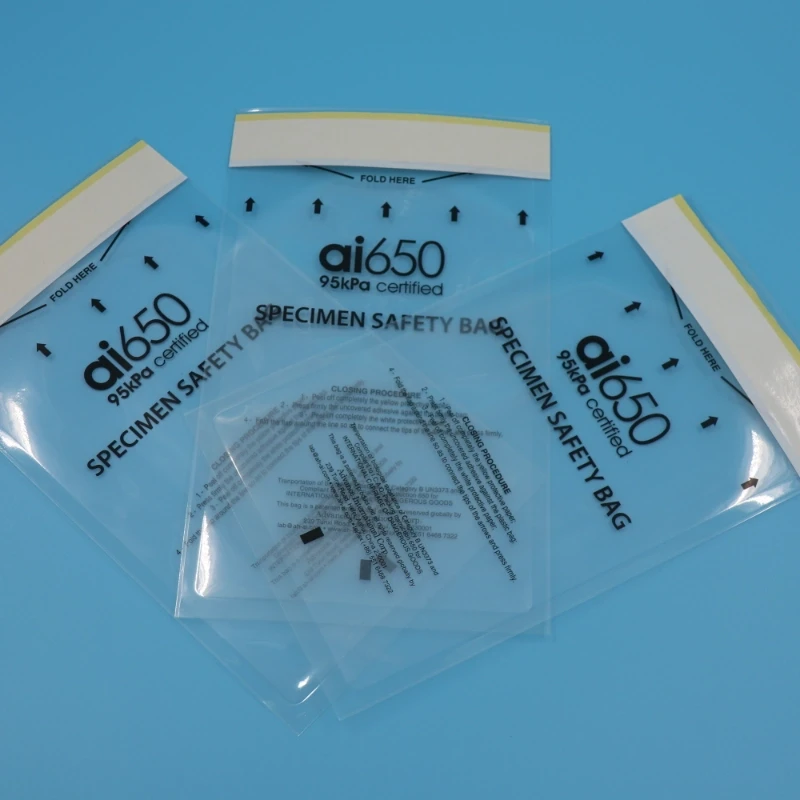

Medical & Laboratory Use

- Sterilization Autoclave Bags: Designed to withstand high-pressure steam (around 100–150 kPa) during sterilization.

- IV Fluid Bags: Must maintain structural integrity under varying pressure during administration.

- Biomedical Waste Containers: Prevent leaks under pressure during disposal.

Industrial & Food Packaging

- Vacuum-Sealed Bags: Used in food packaging to remove air (creating a vacuum of ~80–90 kPa), extending shelf life.

- Compressed Gas Storage: Bags for transporting CO₂ or nitrogen cartridges rated to handle high internal pressure

Outdoor & Sports Gear

- Dry Bags for Diving/Boating: Rated to resist water pressure at depth (e.g., 10–30 kPa for shallow diving).

- Inflatable Air Chambers: In camping mattresses or life rafts, maintaining air pressure without rupturing

Aerospace & Automotive

- Component Packaging: Protects sensitive parts from pressure changes during flights or high-speed transport.

How Are kPa Bags Tested?

Manufacturers test kPa bags using methods like:

- Burst Testing: Increasing internal pressure until failure to determine maximum tolerance.

- Creep Testing: Applying constant pressure over time to assess long-term durability.

- Vacuum Testing: Simulating low-pressure environments to check for leaks or collapse.

Materials like reinforced plastics, laminated films, or rubber-coated fabrics are chosen based on their tensile strength and flexibility.

Choosing the Right kPa Bag

When selecting a kPa-rated bag, consider:

- Pressure Range: Match the bag’s rating to your use case ,e.g., a 150 kPa bag for autoclaving.

- Material Compatibility: Ensure the bag resists chemicals, temperature, or abrasion in your environment.

- Certifications: Look for industry-specific standards ,e.g., FDA-approved for medical use.

- Seal Type: Heat-sealed, zip-lock, or valve closures affect pressure retention.

The Future of kPa Bags

As industries demand smarter, sustainable solutions, innovations are emerging:

- Biodegradable Pressure-Resistant Films: Reducing environmental impact.

- Smart Sensors: Bags with built-in pressure monitors for real-time alerts.

- Lightweight Composites: For aerospace and military applications.

kPa bags might seem like a niche product, but they play a vital role in ensuring safety, efficiency, and reliability across countless fields. Whether you’re sterilizing medical tools, preserving food, or exploring the ocean depths, understanding pressure ratings helps you choose the right tool for the job.