What is Advanced Recycling’s Role in Medical Packaging?

Release time: 2025-04-08

As the global healthcare sector faces mounting pressure to reduce its environmental footprint, advanced recycling is emerging as a game-changer for sustainable medical packaging. Unlike traditional mechanical recycling, advanced methods like chemical recycling and pyrolysis can break down complex plastics into raw materials without compromising quality—a critical factor for sterile, high-performance medical packaging. Here’s how this technology is reshaping the industry.

The Challenge of Medical Packaging Waste

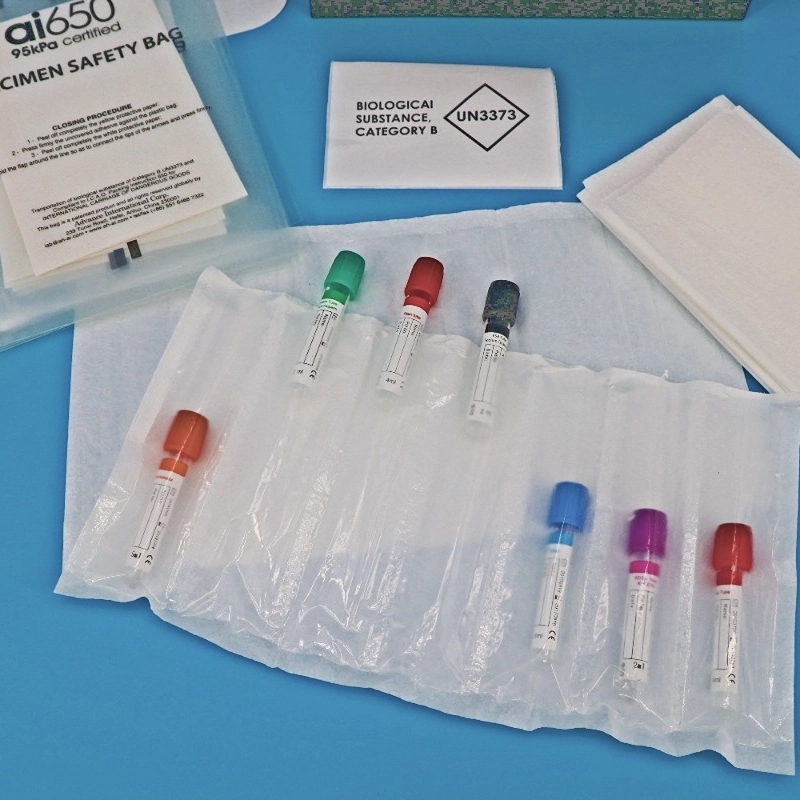

Medical packaging accounts for 30% of healthcare-related plastic waste, driven by strict safety standards that prioritize single-use, multilayered materials. These include:

High-barrier films : e.g., IV bag packaging.

Tyvek® pouches for sterile devices.

Multilayer laminates combining plastics, aluminum, and adhesives.

Most of these materials are incinerated or landfilled due to contamination risks and recycling complexity.

How Advanced Recycling Bridges the Gap

Advanced recycling technologies target materials deemed “unrecyclable” by conventional methods:

Chemical Recycling

Breaks plastics into monomers or hydrocarbons using solvents or heat.

Example: Eastman’s Molecular Recycling converts PET-based medical packaging into virgin-grade materials.

Pyrolysis

Heats plastics in oxygen-free environments to produce oil for new plastics.

Case Study: BASF’s ChemCycling™ processes mixed plastic waste from medical device packaging.

Enzymatic Recycling

Uses engineered enzymes to decompose polymers like polypropylene.

Startups like Carbios are piloting this for medical-grade plastics.

Advantages for the Medical Sector

a. Closed-Loop Solutions: Recover materials for FDA-compliant packaging without downcycling.

b. Contamination Tolerance: Safely handles post-consumer medical waste (e.g., residue-free syringes).

c. Carbon Reduction: Pyrolysis-based recycling can cut CO2 emissions by 50% vs. virgin plastic production.

Industry Adoption & Barriers

1.Pioneers in Action:

Amcor: Partnered with Licella to develop chemically recycled medical pouches.

BD (Becton Dickinson): Piloting pyrolysis-recycled PET for syringe packaging.

2.Challenges:

High Costs: Advanced recycling plants require significant CAPEX.

Regulatory Hurdles: FDA approval for recycled materials in sterile packaging remains stringent.

Feedstock Consistency: Medical waste streams vary widely, complicating processing.

The Road Ahead

1.Policy Push: The EU’s PPWR (Packaging and Packaging Waste Regulation) mandates recycled content in medical packaging, accelerating investment.

2.Tech Innovations: AI-driven sorting systems (e.g., AMP Robotics) improve feedstock purity for medical-grade recycling.

3.Collaborative Models: Hospitals, waste managers, and brands like Johnson & Johnson are forming consortia to standardize collection.